Clamping Force 1800 Tons Injection Molding Machine 1-8 Zone PLC Control 50-4000G Capacity

Product Details:

| Place of Origin: | Ningbo,China |

| Brand Name: | Haijiang |

| Certification: | ISO9001,CE |

| Model Number: | HJF-1000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | 20000 USD |

| Packaging Details: | standard shipping packing |

| Delivery Time: | 35 days |

| Payment Terms: | TT,LC,DP |

| Supply Ability: | 300 sets per month |

|

Detail Information |

|||

| Mold Thickness: | 150-1000 Mm | Clamping Force: | 1800Tons |

|---|---|---|---|

| Heating Zone: | 1-8 | Injection Capacity: | 50-4000 G |

| Control System: | PLC | Heating Power: | 1-50 KW |

| Injection Pressure: | 150-3000 Bar | Ejector Force: | 1-50 KN |

| High Light: | 1800 Tons Injection Molding Machine,50-4000G Injection Molding Machine,PLC Control Injection Molding Machine |

||

Product Description

Product Description:

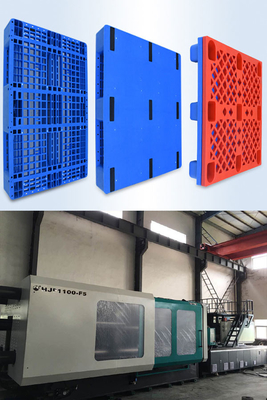

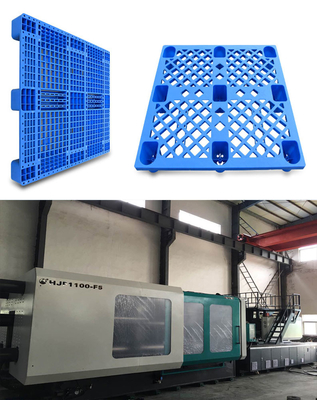

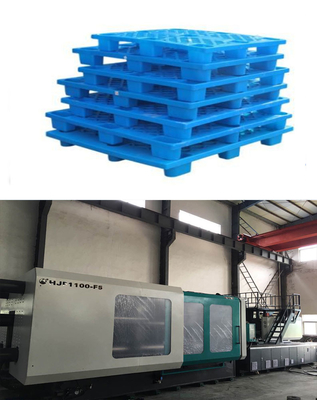

The Plastic Injection Molding Machine is a state-of-the-art manufacturing solution designed to create a wide range of plastic parts, including high-precision bottle caps, which are essential components in the packaging industry. This machine stands out in the market due to its robust construction, advanced control systems, and exceptional performance in producing intricate and high-quality plastic products.

At the core of this machine's functionality is its screw diameter range, which spans from 15 mm to a substantial 250 mm. This feature allows for a versatile processing capability, accommodating various plastic materials and ensuring that the machine can be adjusted to meet the specific requirements for each unique project, including the production of injection moulding machine for bottle caps. The screw mechanism is intricately designed to deliver a consistent plasticizing flow, which is crucial in maintaining the integrity of the molded products.

The Plastic Injection Molding Machine boasts an ejector stroke ranging from 50 mm to an impressive 300 mm. This broad range ensures that ejected parts can be accommodated with ease, regardless of their size. The efficient ejection system plays a pivotal role in the seamless operation of the machine, contributing to the high-speed production and minimizing downtime between cycles. This feature is especially important when dealing with high-output tasks, such as the creation of plastic components for consumer goods.

Clamping is an essential aspect of the injection molding process, and this machine offers a clamping stroke that ranges from 100 mm to a substantial 1000 mm. This wide clamping stroke range ensures that the machine can handle a variety of mold sizes, making it an extremely flexible option for manufacturers looking to produce a diverse array of plastic parts. The clamping system is engineered to apply even and precise force, ensuring that molds are securely closed during the injection process, which is crucial for achieving impeccable product quality.

Injection pressure is another critical factor in the injection molding process, and this machine excels with an injection pressure ranging from 150 bar to a powerful 3000 bar. Such a high-pressure range enables the machine to inject molten plastic into the mold with high precision and speed, ensuring that even the most complex and detailed parts are filled accurately. This level of control is particularly important when manufacturing products that require tight tolerances and fine features, such as injection moulding machine for bottle caps.

When considering the acquisition of a Plastic Injection Molding Machine, potential buyers are often concerned about the puf injection machine price. It is important to note that this machine represents a significant investment in productivity and quality. Its ability to produce high volumes of plastic parts efficiently and with minimal waste makes it a cost-effective solution in the long run. The machine's energy-efficient design and low maintenance requirements also contribute to a lower total cost of ownership, making it a smart choice for businesses looking to optimize their production processes.

In conclusion, the Plastic Injection Molding Machine is a versatile and powerful tool for any manufacturer aiming to produce high-quality plastic parts. With its wide range of screw diameters, ejector strokes, clamping strokes, and high injection pressures, this machine is capable of tackling various production challenges. Whether you are in the market for an injection moulding machine for bottle caps or any other plastic components, this machine's performance, reliability, and competitive puf injection machine price make it an attractive option for businesses committed to excellence in plastic manufacturing.

Features:

- Product Name: Plastic Injection Molding Machine

- Ejector Force: 1-50 KN

- Injection Pressure: 150-3000 Bar

- Type: Plastic Injection Molding Machine

- Heating Zone: 1-8

- Ejector Stroke: 50-300 Mm

- Perfect for injection moulding machine for bottle caps

- Competitively priced, similar to used 80 ton injection molding machine price

- Affordable puf injection machine price

Technical Parameters:

| Parameter | Specification |

|---|---|

| Clamping Force | 1800Tons |

| Type | Plastic Injection Molding Machine |

| Screw Length-Diameter Ratio | 12-20 |

| Nozzle Temperature | 50-400℃ |

| Ejector Stroke | 50-300 mm |

| Heating Power | 1-50 KW |

| Mold Thickness | 150-1000 mm |

| Injection Pressure | 150-3000 Bar |

| Injection Capacity | 50-4000 g |

| Screw Diameter | 15-250 mm |

Applications:

The Haijiang brand, known for its reliable and efficient plastic injection molding machines, offers the HJF-180 model, which has become a staple in the plastic manufacturing industry. This robust machine, originating from Ningbo, China, carries the assurance of quality with ISO9001 and CE certifications, making it a trustworthy choice for plastic producers.

With a minimum order quantity of just one set and a competitive price of 20000 USD, the HJF-180 is accessible to both small and large-scale operations. The standard shipping packing ensures that the machine arrives at its destination in optimal condition, ready for immediate use. A delivery time of just 35 days and flexible payment terms, including TT, LC, and DP, make the procurement process smooth and customer-friendly.

Haijiang's HJF-180 boasts a clamping force of 1800 tons, making it suitable for producing a wide range of plastic products. The screw diameter ranges from 15 to 250 mm, combined with a heating zone that can be configured from 1 to 8, ensuring precise control over the molding process. The injection capacity of 50-4000 g accommodates various sizes of product manufacturing, while the screw length-diameter ratio of 12-20 enhances the quality and efficiency of the plastic injection process.

For businesses looking at the used 80 ton injection molding machine price, the HJF-180 offers a new and advanced alternative that delivers superior performance and longevity. It is a cost-effective solution that justifies the initial investment by reducing maintenance costs and downtime compared to older, used machines.

Startups and small-scale ventures considering the small plastic molding machine price will find the HJF-180's features to be an upgrade, providing more power and versatility for a marginal cost increase. Similarly, for those in the market for a puf injection machine price, the HJF-180 presents an option that can exceed expectations in both functionality and output quality.

Haijiang’s commitment to excellence is evident in the HJF-180’s supply ability of 300 sets per month, ensuring that demand is met promptly and efficiently. This machine is an essential tool for any plastic manufacturing operation looking to produce high-quality plastic parts with precision and speed.

Customization:

Brand Name: Haijiang

Model Number: HJF-180

Place of Origin: Ningbo, China

Certification: ISO9001, CE

Minimum Order Quantity: 1 set

Price: 20000 USD

Packaging Details: standard shipping packing

Delivery Time: 35 days

Payment Terms: TT, LC, DP

Supply Ability: 300 sets per month

Injection Capacity: 50-4000 G

Screw Length-Diameter Ratio: 12-20

Ejector Force: 1-50 KN

Mold Thickness: 150-1000 Mm

Nozzle Temperature: 50-400℃

Experience precision and efficiency with the Haijiang HJF-180, a high-performance 180 ton injection moulding machine tailored for a variety of applications, including injection moulding machine for bottle caps . With a competitive 180 ton injection moulding machine price , this equipment is an excellent alternative to a used 80 ton injection molding machine , offering advanced features and reliability at a great value. Contact us to enhance your production with the HJF-180 today.

Support and Services:

Our Plastic Injection Molding Machine comes with comprehensive technical support and services designed to ensure that you get the most out of your equipment. With a focus on reliability and efficiency, our expert team is dedicated to helping you maximize productivity and minimize downtime. Our support includes the following:

Installation Assistance: We offer guidance through the installation process to ensure that your machine is set up correctly and ready for operation.

Training Programs: Our training programs are tailored to your needs, providing your staff with the knowledge and skills required to operate the machinery effectively and safely.

Troubleshooting: In case of any operational issues, our technical support team is skilled in diagnosing and addressing problems quickly, minimizing any potential disruptions to your production line.

Maintenance Services: Regular maintenance is critical to the longevity and performance of your Plastic Injection Molding Machine. We provide scheduled maintenance services to keep your machine in top condition.

Replacement Parts: We supply a full range of replacement parts for our machines, ensuring that any worn or damaged components can be replaced promptly to maintain optimal functionality.

Software Updates: Our machines are equipped with the latest technology, and we provide software updates as needed to keep your equipment up to date with the newest features and improvements.

Remote Monitoring: For select models, we offer remote monitoring capabilities, allowing our support team to assess and optimize your machine's performance from afar.

Technical Consultation: Our team is available to provide expert advice on process optimization, material selection, and any other technical inquiries you may have regarding our Plastic Injection Molding Machines.

We are committed to providing exceptional support and services to ensure that our Plastic Injection Molding Machines meet your manufacturing needs and exceed your expectations.

Packing and Shipping:

The Plastic Injection Molding Machine will be securely packaged in a robust wooden crate designed to withstand the rigors of international shipping. The crate will be internally padded with shock-absorbing materials to ensure the machine is immobile during transit, effectively protecting it from vibrations and impacts.

Before the shipping process, the machine will be thoroughly inspected and wrapped in a protective plastic film to guard against moisture and dust. All sensitive components of the machine will be additionally protected with foam padding or bubble wrap to prevent any damage during handling.

The wooden crate will be sealed and banded with metal straps for added structural integrity, and the exterior will be clearly marked with the necessary shipping labels, handling instructions, and cautionary symbols to ensure proper transportation protocol is followed. A packing list will be attached to the outside of the crate, providing details of the contents and serving as a checklist upon receipt.

For international shipping, the crate will be compliant with ISPM 15 regulations for wood packaging to prevent the spread of pests and diseases across borders. The machine will be loaded onto a cargo pallet, allowing for easy handling by forklifts and pallet jacks at the destination.

Upon dispatch, the consignment will be insured and a tracking number will be provided, enabling real-time tracking of the shipment until it safely reaches its destination. Delivery shall be made to the address specified by the buyer, and any special delivery instructions must be communicated prior to shipping.

FAQ:

Q1: What is the brand and model number of the injection molding machine?

A1: The brand is Haijiang, and the model number is HJF-180.

Q2: Where is the Haijiang HJF-180 injection molding machine manufactured?

A2: It is manufactured in Ningbo, China.

Q3: Does the Haijiang HJF-180 come with any certifications?

A3: Yes, it comes with ISO9001 and CE certifications.

Q4: What is the minimum order quantity for the Haijiang HJF-180?

A4: The minimum order quantity is 1 set.

Q5: What are the packaging details for this machine?

A5: The machine comes with standard shipping packing.

Q6: How long does it take to deliver the Haijiang HJF-180 injection molding machine?

A6: The delivery time is approximately 35 days.

Q7: What are the payment terms for purchasing this machine?

A7: The payment terms are TT (Telegraphic Transfer), LC (Letter of Credit), and DP (Document against Payment).

Q8: How many sets of the HJF-180 can Haijiang supply each month?

A8: Haijiang can supply up to 300 sets per month.

Q9: What is the price for one set of Haijiang HJF-180?

A9: The price for one set is 20,000 USD.