PP Thickened Non Slip Stool Injection Molding Machine With High Output

Product Details:

| Place of Origin: | Ningbo, China |

| Brand Name: | HAIJIA |

| Certification: | CE/ISO9001 |

| Model Number: | HJF240 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 piece |

|---|---|

| Price: | USD 24923/piece |

| Packaging Details: | Standard Export Package |

| Delivery Time: | 25days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5000 pieces per Year |

|

Detail Information |

|||

| Condition: | New | Automatic: | Full Automatic |

|---|---|---|---|

| Type: | Plastic Injection Molding Machine | Style: | Horizontal |

| Warranty: | 18 Months | ||

| High Light: | PP Thickened Stool Injection Moulding Machine,Non Slip Stool Injection Molding Machine |

||

Product Description

PP thickened non-slip stool injection moulding molding machine with high quality and output

![]()

![]()

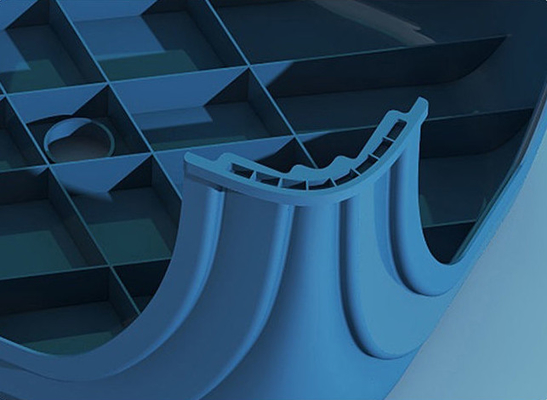

Injection Molding Machine HJF240

Adjustment Unit

Automatic Mold Height Adjustment Saves the time and cost during the mold changing.

Clamping Unit

The plates were designed using FEM software, ensuring a stable and rigid clamping system. Five point inward moving double toggle system ensures high rigidity and precision for mold clamping and also reducing stress and Strain effects.

Hydraulic Unit

The hydraulic system using the world famous pump and control valve can control the machine running precisely, ensuring the precision, reliability and durability of whole machine.

Injection Unit

Dual-pillar supporting and dual-cylinder injection balance devices ensure the stress on screw balanced during injection.

Specific screw and barrel designs are available for processing different material requirements.

Electronically Controlled Unit

1.CPU controller and display are independent and reliable.

2.A larger color LCD screen enhances clear display and supports Multi language compatibility.

3.The control system also supports remote monitor. In the event of a control problems, the machine can be connected to internet through a special interface. Inject service can realize remote fault diagnosis and maintenance.

4.A screen saver function extends the LCD life.

5.Ultra bright LED is provided for input and output point inspection. Proving convenient indication of the machine’s operation and machine service

6.A data hardware lock is provided to prevent unauthorized people from effecting the machines performance.

7.Closed Loop PID barrel temperature control.

8.Dust and waterproof control cabinets provide a neat and tidy enclosure all electrical control components.

| SPECIFICATION | HJF240 | |||

| Screw Type | A | B | C | |

| Screw Diameter | Mm | 50 | 55 | 60 |

| Screw L/D Ration | L/D | 22.2 | 20 | 18.2 |

| Shot Size(Theoretical) | cm3 | 508 | 593 | 706 |

| Injection Weight(PS) | g | 462 | 534 | 642 |

| Injection Rate | g/s | 148 | 179 | 202 |

| Injection Pressure | MPa | 180 | 160.8 | 128 |

| Screw Speed | rpm | 0~180 | ||

| Clamping Force | KN | 2400 | ||

| Opening stroke | Mm | 490 | ||

| Space Between Tie Bars | mm | 530*510 | ||

| Max.Mold Height | mm | 530 | ||

| Min.Mold Height | mm | 200 | ||

| Ejector Stroke | mm | 165 | ||

| Ejector Tonnage | KN | 70 | ||

| Max.Pump Pressure | MPa | 16 | ||

| Motor Power | KW | 25.1 | ||

| Heater power | KW | 11.65 | ||

| Machine Dimension(L*W*H) | M | 5.4*1.5*2 | ||

| Machine weight | T | 7 | ||

| Oil Tank Capacity | L | 340 | ||

Hydraulic System:

1.) The double proportional compound valve control system pressure & flow, highly sensitive & stable

2.) Imported high quality Pump, low in noise, long in lifespan & stable in performance

3.) World-famous servo hydraulic system optional, better performance in lower noise & energy saving

4.) The precise feedback control of servo system to the pressure & flow, with higher sensitivity & more accurate repeatability precision

5.) High performance hydraulic valve, less failure, fast switch, convenient maintenance

6.) Low pressure mold protect system, which is more suitable for the precise mould

7.) Greese & lubrication oil in dependent lubrication system can lubricate everywhere in the best situation

Electrical System:

1.) Control by double CPU, the system HMI use X86 300MHz technical grade display. The system employees a RISC 140MHz microprofessor, with high speed, noise-immunity, fan-less and lower power consumption, independent control structure improve the stablity of control

2.) 8.4" display screen with resolution 800*600, user friendly screen & optional choose of language

3.) Equiped with USB(2.0) port & ethernet(100-base T) ports

4.) 32 Points input & output, entendable and trouble spot can be replaced easily

5.) Linder transducer's resolution is 1/65535, more precise in control

6.) 120 technological parameters access can be stored & uploaded with an ordinary USB drives

7.) Injection End and temperature tracking is curve display, dynamic recorder parameter is modified, dynamic warningis exhibited, all these make the operation more convenient.

Servo Controller Part:

1.) High Precise Control The servo system can control the machine's pressure, speed & location precisely, make sure that the error of accurate repeatability precision for the shot measurement is <0.3%

2.) High sensitive response Because the motor vector is matched with the controller accurately, it only takes 0.5sec. inputing the number from 0 to max. Compared with other traditional hydraulic injection molding machine, HJS series is more faster in speed with shorter cycle time and high efficient in production

3.) Low noise Compared with traditional fixed pump & variable pump system, the noise is 1/10 lower under normal circumstance, more suitable for sealed dustless workshop

4.) Energy Saving Overall efficiency is 10% more & driving capacity is 18% more than common machine. This series can save 40-80% energy, and achieve first-class energy efficency

5.) Water cooling saving The system condition prevent high pressure uploading without any power output, leads to the water cooling saving

FAQ

Q1. What is the warranty for the plastic injection molding machine

A1:Total 18 month,Included machine platen,base,injection unit,clamping unit.

Q2:Can you sending engineer to oversea install machine and trainning customer's workers.

Q2: Yes,We will send engineer to customer factory install the machine or trainning customer's workers. in one week,total free. After one week, 150$ per day

Q3:How Many spare parts you will prepare for customer?

A3: Spare parts included: mould clamp, long and short nozzle,heating band,Wrench,Switch,Thermocouple,Operation manual,Tool box,Lubricate Oil,Sealing,Filter etc.

Q4:Computer sytem,Except English, can you change other language,say: French,Spanish,Arabic,Russian.

A1:Yes,when you place order,please tell us the language which you required. Standard one with English,Japanese,Chinese,Korea.

Q5:Can you change the power source for us? Say:we need 3 Phase 220V 60HZ

A5: When you place order,please write clearly.Then we will change the electric system for you.

Q6:If i Need Green Color machine,can you do it for us?

Q7: Yes,please give us the color sample.So we can do it for you.