Hot Runner System Injection Molding Molds For Products With Customized Design

Product Details:

| Place of Origin: | Ningbo,China |

| Brand Name: | Haijiang |

| Certification: | ISO9001,CE |

| Model Number: | HJF-780 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | 30000 |

| Packaging Details: | standard shipping packing |

| Delivery Time: | 35 days |

| Payment Terms: | TT,LC,DP |

| Supply Ability: | 300 sets per month |

|

Detail Information |

|||

| Mould CorePulling System: | Hydraulic | Shape: | Customized |

|---|---|---|---|

| Tolerance: | 0.01mm | Mould Testing: | Leakage/Stress |

| Mould Insert: | SKD61 | Mould EjectionSystem: | Hydraulic/Pneumatic |

| Mould Cooling System: | Water/Oil | Color: | Silver |

| High Light: | Hot Runner System Injection Molding Molds,Customized Injection Molding Molds |

||

Product Description

![]()

![]()

![]()

Product Description:

Injection Molding Molds

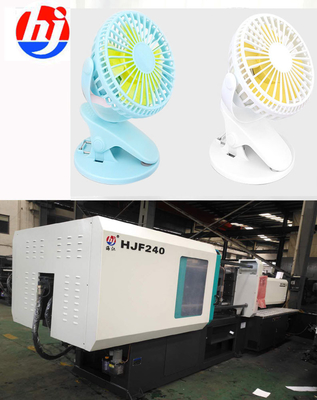

Injection Molding Molds are customized products that are used in the process of injection molding. They are designed to create high-quality and precise products by injecting molten material into a mold cavity. These molds are an essential component of the microprocessor injection molding machine, which is a highly advanced and automated machine used in the manufacturing industry.

The shape of the Injection Molding Molds can be customized according to the specific requirements of the product. This allows for the creation of unique and complex shapes that cannot be achieved through traditional manufacturing methods. The molds are made of high-quality steel, which ensures durability and longevity.

One of the key features of Injection Molding Molds is the hydraulic mold core pulling system. This system allows for precise and efficient movement of the mold core, which is essential for creating intricate and detailed products. The hydraulic system also contributes to the overall speed and accuracy of the injection molding process.

To ensure the highest quality of the final product, the molds undergo a polishing treatment. This process involves smoothing out any imperfections on the surface of the mold, which can affect the final product's appearance and functionality. The polished surface also makes it easier to release the molded product from the mold, resulting in a more efficient production process.

Injection Molding Molds are available in both single and multi-cavity designs. The single cavity molds are used for creating one product at a time, while the multi-cavity molds can produce multiple products in one cycle. This allows for a higher production rate and increased efficiency, making it the preferred choice for large-scale manufacturing.

In conclusion, Injection Molding Molds are essential products in the manufacturing industry, particularly in the production of complex and high-quality products. Their use in the microprocessor injection molding machine with a hydraulic mold core pulling system and polished surface treatment guarantees precision, efficiency, and durability in the injection molding process.

Features:

- Product Name: Injection Molding Molds

- Mould Core: H13

- Tolerance: 0.01mm

- Shape: Customized

- Mould EjectionSystem: Hydraulic/Pneumatic

- Mould Life: 100000 Shots

- Key Features:

- High-quality mould core material H13 ensures durability and long service life

- Precision engineering with a tolerance of 0.01mm for precise and accurate moulding

- Customized shape options to meet specific product requirements

- Efficient hydraulic/pneumatic ejection system for smooth and fast mould release

- Compatible with aotai injection molding machine, battenfeld molding machine, and microprocessor injection moulding machine for versatile use

Technical Parameters:

| Product Name | Injection Molding Molds |

|---|---|

| Mould Base | LKM |

| Tolerance | 0.01mm |

| Mould Cooling System | Water/Oil |

| Mould Testing | Leakage/Stress |

| Mould Insert | SKD61 |

| Mould Life | 100000 Shots |

| Mould Ejection System | Hydraulic/Pneumatic |

| Color | Silver |

| Runner System | Hot/Cold |

| Surface Treatment | Polishing |

| Key Features | battenfeld molding machine, battenfeld molding machine, battenfeld molding machine |

Applications:

Haijiang

HJF-780

Ningbo, China

ISO9001, CE

1 set

30000

Standard shipping packing

35 days

TT, LC, DP

300 sets per month

The Injection Molding Molds - Haijiang HJF-780 is a high-quality, precision plastic injection moulding machine designed for various applications. It is manufactured by Haijiang, a leading company in the field of injection molding technology. This machine is widely used in industries such as automotive, electronics, household appliances, and more.

The HJF-780 model is equipped with a microprocessor control system, allowing for precise and efficient operation. It also has a mould insert made of SKD61, a high-quality steel known for its excellent durability. The silver color and steel material give the machine a sleek and professional appearance. The mould base is made by LKM, a reputable manufacturer known for their high-quality products.

The mould cooling system can be either water or oil-based, depending on the specific needs of the product being manufactured. This allows for greater flexibility and customization in the production process.

The HJF-780 has been certified with ISO9001 and CE, ensuring that it meets the highest quality standards. It also has a minimum order quantity of 1 set, making it suitable for both small and large-scale production. With a supply ability of 300 sets per month, Haijiang is able to meet the demands of their customers in a timely manner.

Investing in the Injection Molding Molds - Haijiang HJF-780 means investing in high-quality, efficient, and precise production. Whether you are in the automotive, electronics, or household appliance industry, this machine is a valuable asset to your business.

Customization:

Brand Name: Haijiang

Model Number: HJF-780

Place of Origin: Ningbo, China

Certification: ISO9001, CE

Minimum Order Quantity: 1 set

Price: $30,000

Packaging Details: Standard shipping packing

Delivery Time: 35 days

Payment Terms: TT, LC, DP

Supply Ability: 300 sets per month

Material: Steel

Mould Cavity: Single/Multi

Mould Ejection System: Hydraulic/Pneumatic

Runner System: Hot/Cold

Tolerance: 0.01mm

This customizable Injection Molding Molds service from Haijiang offers top-of-the-line quality and precision for your production needs. Our microprocessor injection moulding machine and battenfeld molding machine are designed to meet the highest standards and deliver consistent results. With our expertise and advanced technology, we can customize the mould cavity, ejection system, and runner system according to your specific requirements. Our molds are made of high-quality steel and have a tolerance of 0.01mm, ensuring durability and accuracy. Trust Haijiang for all your injection molding needs and experience the difference in performance and efficiency.

Packing and Shipping:

Our Injection Molding Molds are carefully packaged to ensure safe delivery to our customers. Each mold is wrapped in protective materials and placed in a sturdy box to prevent any damage during shipping.

We offer various shipping options to meet the needs of our customers. Our products can be shipped internationally to ensure that our molds can reach customers all around the world.

For small orders, we use air freight to expedite delivery. For larger orders, we have partnerships with reliable shipping companies to ensure timely and efficient delivery.

Our packaging and shipping process is designed to minimize any potential delays or damages, so that our customers can receive their molds in perfect condition.

At Injection Molding Molds, we take great care in packaging and shipping our products, so that our customers can have a hassle-free experience and receive the highest quality molds.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is Haijiang. - Q: What is the model number of this product?

A: The model number of this product is HJF-780. - Q: Where is this product manufactured?

A: This product is manufactured in Ningbo, China. - Q: Has this product received any certifications?

A: Yes, this product has received ISO9001 and CE certifications. - Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 1 set. - Q: How much does this product cost?

A: The price for this product is 30000 USD. - Q: What type of packaging is used for shipping this product?

A: This product is shipped using standard shipping packing. - Q: How long is the delivery time for this product?

A: The delivery time for this product is 35 days. - Q: What are the accepted payment terms for this product?

A: The accepted payment terms for this product are TT, LC, and DP. - Q: What is the supply ability of this product?

A: The supply ability for this product is 300 sets per month.