Plastic color chair beach chair leisure chair injection molding machine

Product Details:

| Place of Origin: | Ningbo,China |

| Brand Name: | Haijiang |

| Certification: | ISO9001,CE |

| Model Number: | HJF-780 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD 36000 |

| Packaging Details: | standard shipping packing |

| Delivery Time: | 35 days |

| Payment Terms: | TT,LC,DP |

| Supply Ability: | 300 sets per month |

|

Detail Information |

|||

| Tolerance: | 0.01mm | Mould Core: | H13 |

|---|---|---|---|

| Color: | Silver | Mould EjectionSystem: | Hydraulic/Pneumatic |

| Mould Testing: | Leakage/Stress | Mould Base: | LKM |

| Mould CorePulling System: | Hydraulic | Mould Insert: | SKD61 |

Product Description

Product Description:

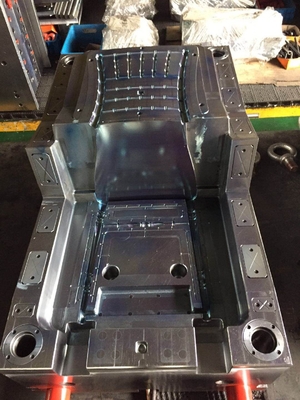

Injection Molding Molds are essential tools used in the manufacturing process of various plastic products. These molds are designed and manufactured to precision in order to produce high-quality and consistent plastic parts for a wide range of industries such as automotive, electronics, medical, and consumer goods.

The Injection Molding Molds are made of high-quality steel material, specifically SKD61 for the mould insert and H13 for the mould core. These materials are known for their durability, heat resistance, and ability to withstand high pressures. This ensures that the molds can withstand the high temperatures and pressures involved in the injection molding process, resulting in precise and accurate plastic parts.

The Injection Molding Molds are equipped with a highly efficient cooling system that uses either water or oil. This system ensures that the molds maintain a stable and optimal temperature during the injection process, preventing any warping or defects in the final product. The cooling system also helps to reduce cycle time, increasing productivity and efficiency.

Our Injection Molding Molds are designed to be compatible with Aotai injection molding machines. Aotai is a leading manufacturer of microprocessor injection moulding machines, known for their precision and reliability. This compatibility ensures seamless integration and optimal performance, resulting in high-quality plastic parts.

The Injection Molding Molds have a long mould life of up to 100,000 shots. This is due to the high-quality materials used in their construction, as well as the precision in the design and manufacturing process. This ensures that our customers can rely on our molds for consistent and high-quality production over an extended period of time, saving them time and money in the long run.

Overall, our Injection Molding Molds are a crucial component in the injection molding process, providing precision, durability, and efficiency. With high-quality materials, efficient cooling systems, and compatibility with Aotai injection molding machines, our molds are the perfect choice for producing high-quality plastic parts for various industries. Contact us today to learn more about our Injection Molding Molds and how they can benefit your production process.

Features:

- Product Name: Injection Molding Molds

- Mould Insert: SKD61

- Mould Base: LKM

- Mould Cooling System: Water/Oil

- Mould Core: H13

- Color: Silver

- Aotai Injection Molding Machine

- Microprocessor Injection Moulding Machine

- Aotai Injection Molding Machine

Technical Parameters:

| Product Name | Injection Molding Molds |

|---|---|

| Surface Treatment | Polishing |

| Runner System | Hot/Cold |

| Color | Silver |

| Mould Cavity | Single/Multi |

| Mould Ejection System | Hydraulic/Pneumatic |

| Shape | Customized |

| Tolerance | 0.01mm |

| Material | Steel |

| Mould Life | 100000 Shots |

| Mould Insert | SKD61 |

Key Words: battenfeld molding machine, aotai injection molding machine, aotai injection molding machine

Applications:

Haijiang Injection Molding Molds are high-quality and durable molds for use in a variety of industries. They are designed and manufactured by Haijiang, a leading manufacturer of plastic injection molding machines.

Our Brand Name: Haijiang

Model Number: HJF-780

Place of Origin: Ningbo, China

Certification: ISO9001, CE

Minimum Order Quantity: 1 set

Price: $30,000

Packaging Details: standard shipping packing

Delivery Time: 35 days

Payment Terms: TT, LC, DP

Supply Ability: 300 sets per month

Mould Insert: SKD61

Mould Ejection System: Hydraulic/Pneumatic

Runner System: Hot/Cold

Mould Core Pulling System: Hydraulic

Material: Steel

Haijiang Injection Molding Molds are used in a variety of industries, including automotive, electronics, medical, and consumer goods. They are ideal for producing plastic parts in large quantities with high precision and consistency.

A factory in Ningbo, China is using Haijiang Injection Molding Molds to produce plastic parts for a new line of electronic devices. The factory is equipped with state-of-the-art battenfeld molding machines and aotai injection molding machines, allowing for efficient and precise production.

The machines are operated by highly trained technicians who carefully monitor the molding process to ensure the molds are producing high-quality parts. The molds are designed with advanced technology and are able to produce complex and intricate parts with ease.

The factory floor is bustling with activity as the machines run continuously, producing thousands of plastic parts per day. The finished parts are then inspected and packaged for shipment to customers around the world.

Thanks to Haijiang Injection Molding Molds, the factory is able to meet the high demand for the new electronic devices and maintain a high level of quality in their production.

Whether it's for automotive parts, medical devices, or consumer goods, Haijiang Injection Molding Molds are the top choice for businesses looking for reliable and efficient molds. With their advanced technology, durable materials, and precision design, these molds are sure to meet the needs of any industry and help businesses thrive in the competitive market.

Customization:

Brand Name: Haijiang

Model Number: HJF-780

Place of Origin: Ningbo, China

Certification: ISO9001, CE

Minimum Order Quantity: 1 set

Price: $30,000

Packaging Details: Standard shipping packing

Delivery Time: 35 days

Payment Terms: TT, LC, DP

Supply Ability: 300 sets per month

Shape: Customized

Mould Core Pulling System: Hydraulic

Mould Testing: Leakage/Stress

Mould Cooling System: Water/Oil

Mould Ejection System: Hydraulic/Pneumatic

Our Injection Molding Molds customization service offers high-quality and precise molds for your specific needs. With our microprocessor injection molding machine, aotai injection molding machine, and battenfeld molding machine, we ensure efficient and accurate production of your desired molds.

Packing and Shipping:

Our Injection Molding Molds are carefully packaged and shipped to ensure safe delivery to our customers. Each mold is individually wrapped and protected with foam padding to prevent any damage during transport.

For smaller molds, we use sturdy cardboard boxes reinforced with straps to secure the contents. Larger molds are crated and secured with wooden braces to provide maximum protection during shipping.

We also take great care in labeling each package with handling instructions and product information to avoid any mishandling or confusion during transportation.

Depending on the size and weight of the molds, we use either air or ocean freight services to ship our products. Our experienced logistics team ensures that all necessary customs and shipping documentation are in order to avoid any delays or issues during transit.

We value our customers' time and strive to deliver our products in a timely and efficient manner. Our partnerships with trusted carriers and efficient logistics processes help us to provide reliable and cost-effective shipping options for our customers.

When your order is ready to ship, we will provide you with a tracking number so that you can easily track your package and know when to expect delivery.

Thank you for choosing our Injection Molding Molds. We are committed to providing high-quality products and exceptional customer service. If you have any questions or concerns about your shipment, please do not hesitate to contact us.

FAQ:

- Q: What is the brand name of this product?

A: The brand name is Haijiang. - Q: What is the model number of this product?

A: The model number is HJF-780. - Q: Where is this product manufactured?

A: This product is manufactured in Ningbo, China. - Q: Does this product have any certifications?

A: Yes, it is certified with ISO9001 and CE. - Q: What is the minimum order quantity for this product?

A: The minimum order quantity is 1 set. - Q: What is the price of this product?

A: The price is 30000 USD. - Q: How is this product packaged for shipping?

A: It is packaged with standard shipping packing. - Q: How long is the delivery time for this product?

A: The delivery time is 35 days. - Q: What are the accepted payment terms for this product?

A: The accepted payment terms are TT, LC, and DP. - Q: What is the supply ability for this product?

A: The supply ability is 300 sets per month.