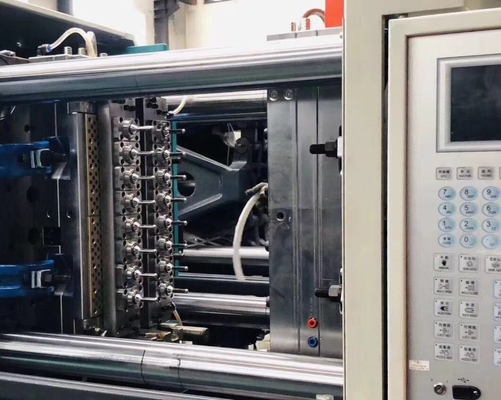

16 Cavities Auto Injection Molding Machine Servo Energy Saving PET Injection Molding Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | Taihong |

| Certification: | ISO9001 |

| Model Number: | HJF1250 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | negotiable |

| Packaging Details: | Export Standard |

| Delivery Time: | 30 days |

| Payment Terms: | TT, L/C, Western Union, MoneyGram |

| Supply Ability: | 500sets/month |

|

Detail Information |

|||

| Shot Weight300rams: | 3744/4530/5392/6328grams | Motor Power: | 110kw |

|---|---|---|---|

| Heating Power: | 59kw | Machine Weight: | 53tons |

| Machine Dimension: | 12.1m*2.9m*3.2m | Name: | Servo Injection Moulding Machine |

| High Light: | pvc pipe fitting injection molding machine,servo motor injection molding machine,hydraulic plastic injection moulding machine |

||

Product Description

16 cavities pet preform molding , Plastic Moulding Machine / Servo Energy Saving PET Injection Molding Machine

Control unit

Name:Techmation PLC Cotroller

Brand: Techmation

Original: TW

Multiple-unit plastic moulding data memory system

it real-timely monitors various actions and gives automatic warning for defects

data protection lock for parameters

motor safety protection device

color warning light

The international famous components, durable and low energy consumption.

Main application

This is a new generation packaging machinery which is developed on the basis of introducing and absorbing the advanced technology from America, Japan and Germany. Adopts top quality components like Japanese Mitsubishi PLC, SMC pneumatic components, American Nordson hot melt adhesive, ensures the carton forming, packing, folding, glue spraying, sealing and the following packaging process continuously and automatically finished. With characteristics of reasonable structure, stable performance, reliable quality, high productivity, wide adaptability, and high degree automation. Widely used in instant noodles, cigarettes, liquor, beverage and other cartoon packaging products

Characteristics

1. Adopts the imported control components, durable, safe, and low failure rate.

2. Use human-computer interface, simple and more visually oriented.

3. The machine uses machine electrical and air linkage, excellent effect of bottom sealing.

4. East to adjust different sizes of cartons, adjust quickly and easily, available for a wide range of cartons.

5. Low power consumption, simple and convenient operation, low noise.

6. Use tap to seal the cartoon bottom, protected from weather, sealing reliable.

Shipping and Payment

| Product Name | 1250 Injection molding machine price |

| Packing | Export standard package |

| MOQ | 1 set |

| FOB price | Please contact for new price |

| Delivery time | 30days |

| FOB port | Ningbo |

| Payment terms | T/T,L/C at sight |

Specification

| Injection Unit | UNIT | A | B | C | D |

| Screw diameter | mm | 100 | 110 | 120 | 130 |

| Screw L/D ratio | L/D | 23 | 22 | 20 | 18.6 |

| Shot size(theoretical) | CM³ | 4160 | 5034 | 5991 | 7031 |

| Injection weight(ps) | g | 3744 | 4530 | 5392 | 6328 |

| Injection rate | g/s | 590 | 720 | 867 | 948 |

| Injection pressure | Mpa | 211 | 174 | 146 | 125 |

| Screw speed | rpm | 100 | |||

| Clamping Unit | |||||

| Clamp tonnage | KN | 12500 | |||

| toggle Stroke | Mm | 1600 | |||

| Space Between tie Bars | mm | 1260*1160 | |||

| Max.mold height | mm | 1300 | |||

| Min.mold height | mm | 500 | |||

| Ejector Stroke | Mm | 360 | |||

| Ejector tonnage | KN | 215 | |||

| Others | |||||

| Max.pump pressure | Mpa | 16 | |||

| Pump motor power | KW | 55+55 | |||

| Heater power | kw | 59 | |||

| Machine size(L x W x H) | m | 12.1*2.9*3.2 | |||

| Machine weight | Ton | 53 | |||

| Oil tank capacity | L | 2206 | |||

![]()

![]()

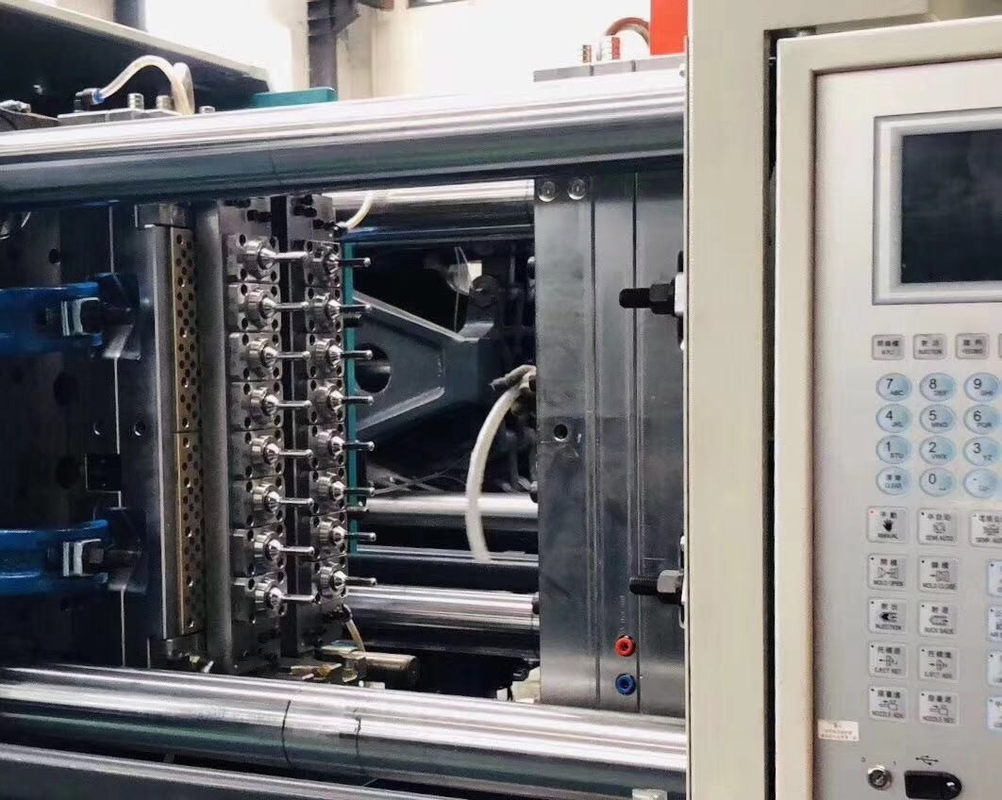

1.Strengthen locking structure

Optimized special locking system to reach efficient and fast production

2.Centralized lubrication, reliable protection

Configuring rational centralized lubrication, providing more professional, better lubrication to make machine more cleaner.

3.Professional templates optimized design

Template by advanced finite element analysis software to optimize design, high rigidity, high strength, to meet the rapid impact conditions demand.

4.Powerful, friendly control system

Adopts professional controller and friendly interface, easy and fast operation, with good reliability.

5.New type screw driving system

Spline connection for screw and oil motor, smooth and reliable transmission, big transfer torque, easy disassembly.

6.Excellent injection performance

Double cylinder injection, entire floor-guided, reliable and stable.

7.Superior clamping system

Adopts optimized connection rod structure, faster and smoother operation.

8.New frame structure

Simple and generous appearance, machine body force reasonable and stronger.

9.Professional plasticizing system

Suitable for different types of plastic raw material with professional plasticizing and heating system, good plasticizing performance.

10High efficient powerful servo system optional

Power system adopts high pressure gear box and servo motor, rotary encoder, pressure transducer and servo amplifier to get system closed-loop control.