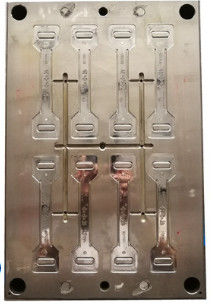

Low Noise Auto Injection Molding Machine 8 Cavities Professional Customization

Product Details:

| Place of Origin: | China |

| Brand Name: | Haijiang |

| Certification: | ISO9001 |

| Model Number: | Plastic handle injection moulds |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | negotiable |

| Packaging Details: | Export Standard |

| Delivery Time: | 15-45days |

| Payment Terms: | T/T |

| Supply Ability: | 30pieces/month |

|

Detail Information |

|||

| Material: | 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 Etc. | System Of Runner: | Hot Runner,Cold Runner,Pin-point Gate,Submarine Gate, Etc |

|---|---|---|---|

| Ejector Type: | Ejector Pin,Air Gate,Ejector Plate,Hydro-cylinder,etc | Product Material: | PP,PE,PC,PA,PS,PU,PVC,PMMA,ABS Etc |

| High Light: | pvc pipe fitting injection molding machine,servo motor injection molding machine |

||

Product Description

| Some details of mould | |

| Name | used plastic trash can injection moldings |

| Mould Material | NAK80,S136,2316,2738,H13,5CrNiMo,718H,P20,40Cr,60#,45# etc |

| Product Material | PP,PE,PC,PA,PS,PU,PVC,PMMA,ABS etc |

| Cavity No. | Single or multi |

| System Of Runner | Hot runner,Cold runner,Pin-point gate,Submarine gate, etc |

| Ejector Type | Ejector pin,Air gate,Ejector plate,Hydro-cylinder,etc |

| Term Of Mould Production | 45days- 60days |

| Guaranteed Number Of Cycles | 300,000-500,000 closing |

| Mould Design Software | Ug,Proe,Solidworks AotoCAD,Moldflow,ect |

| Mould Produce Process | ||

| 1 | Product Design |

Customer send us the product drawing directly or we draw the product according to the sample,then we send customer the product drawing to confirm |

| 2 | Mould Design |

We'll start to design mould after the product drawing confirmed,then send customer the mould drawing to confirm |

| 3 | Mould Making |

The mould start to make after the mould drawing confirmed,the process include prepare steel,rough cut,finish machining,assembly etc |

| 4 | Mould Test |

we'll test the mould after mould assembly,then we'll send customer samples and video of mould test to confirm |

| 5 | Final Process |

The mould start to polish if the sample is ok,and make grain,nitridation or chroming if customer required |

| 6 | Mould Test |

We'll test the mould again after polishing,then send customer the final sample and video of mould test to confirm |

| 7 | Mould Packing |

The mould stard to pack with wooden case after the final sample confirmed, then the mould will be sent to port and waiting for shipping |

Why choose us?our advantages

1.Strict quality control to meet customer's requirements.

2.Competative price to save cost for customer.

3. Good After-sale Service,we'll provide technical support for a long period.

4. Rich experience for export mould.

5.Dunctual delivery to produce products in time for customer.

.